Our Service

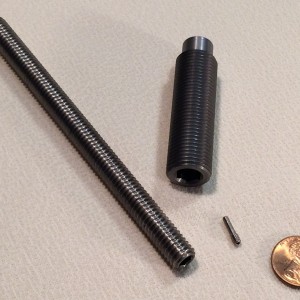

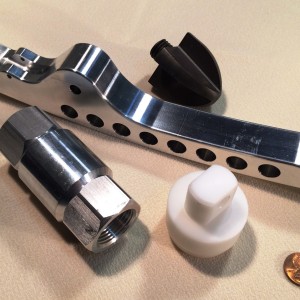

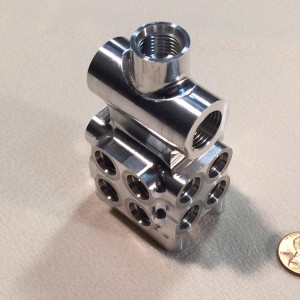

Mahnke Machine provides high quality production of machined parts for many industries using CNC lathes, CNC mills, CNC swiss-screw machines, and B&S automatic screw machines. We are here to assist with the manufacture of your next small to medium production run, (1 to 20,000+ pieces), with technical know-how and experience.

Some of the industries that we serve.

Capabilities, Systems, and Support

- Turning Capacities – Up to 1-1/4″ round thru-spindle capacity for Swiss, Up to 1-3/4″ round for lathes, Up to 4-1/2″ slugs for lathes

- Materials – Aluminum, Brass/Bronze, Copper, Plastic, Steel, Stainless, and exotic materials

- Outside Services – Plating – Zinc, Anodize, Hardcoat, Black Oxide, Passivation, Heat Treating, Grinding – Centerless, ID/OD

- Solidworks 2020 3D Design Software

- PartMaker SwissCAM 2020 Software

- Autodesk FeatureCAM 2020 Software

Major Equipment

- 1 – Tsugami BO326-II – 1-1/4″ capacity

- 1 – Citizen E32 – 1-1/4″ capacity with Long Parts ability

- 1 – Citizen E32 – 1-1/4″ capacity

- 1 – Citizen E25J – 1″ capacity

- 2 – Citizen M12 – 1/2″ capacity

- 1 – Citizen M32 – 1-1/4″ capacity with Long Parts Collector

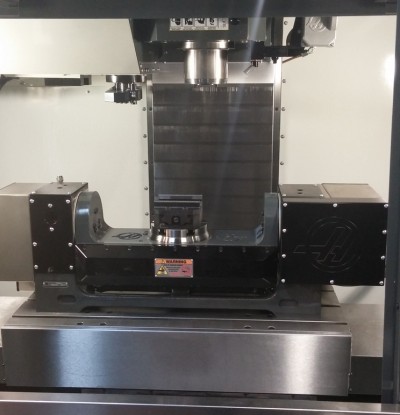

- 1 – Haas VF2SS Mill – 4-axis capable

- 1 – Haas VF2 Mill – 5-axis capable

- 1 – Haas Mini Mill – 4-axis capable

- 1 – Haas SL-10 CNC Lathe

- 5 – Brown & Sharpe automatics – Up to 1-5/8″ capacity (retired)